Hello everyone,

Essential oils are extracted from leaves, flowers, fruit peels, bark, etc. There are various extraction methods, such as steam distillation, pressing, solvent extraction etc. The method is selected according to the characteristics of the plant and the type of fragrance components.

Many people have heard of names of extraction methods but are not familiar with the proper principles or do not know which extraction method is suitable for what kind of plants.

In this 18th edition of FRAGRANCE LAB.BLOG, we will talk about “Extraction of Natural Fragrances Vol. 1: Steam Distillation.”

What is steam distillation?

■Principle

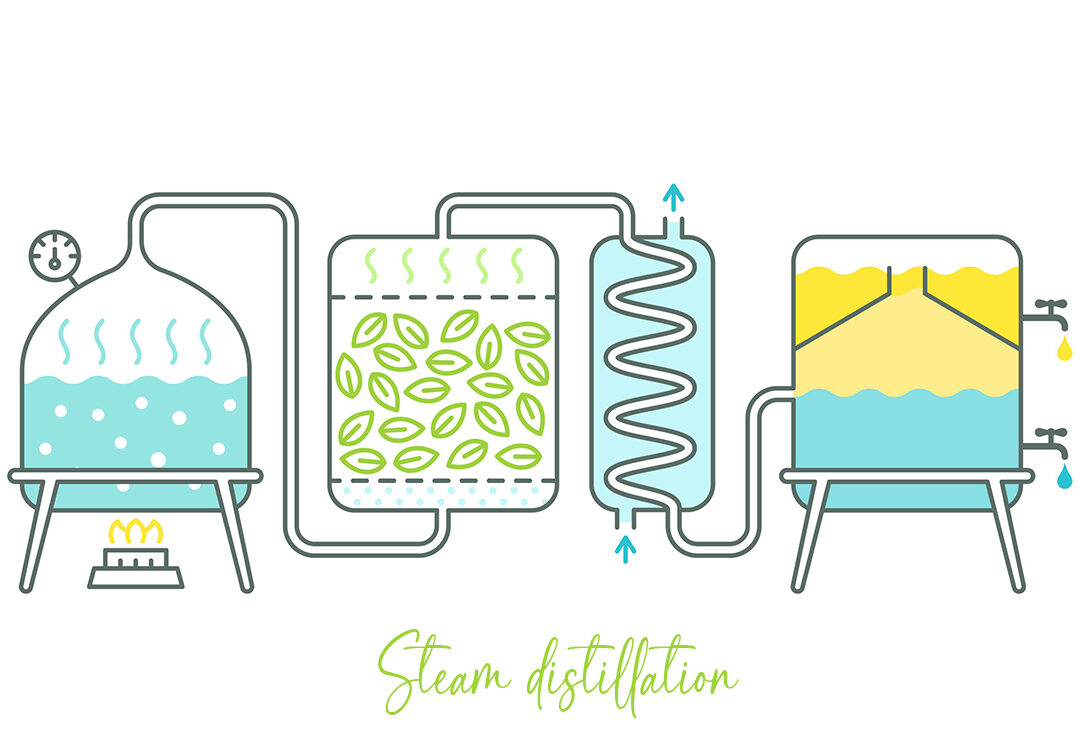

Steam distillation, as the name suggests, is a method of extracting fragrance components from plants using steam (high-temperature vapor). Boiling steam is injected into a still containing plants, and the plants and the steam come into contact inside the still.

The heat of the steam vaporized the aroma components in the plants, and the vapor containing the aroma components flows from the distillation still to the cooling pipes. The vapor is rapidly cooled in the cooling pipes, liquefies, and accumulates in a tank called a separator. Water derived from the vapor and plant-derived oils (essential oil) are extracted in a mixed state, so the water and natural flavors are allowed to stand in the separator until they separate, after which only the essential oil is recovered.

The liquid that is separated from the essential oil is called floral water, hydrolats or hydrosols. It is used for cosmetics and other products.

■Cautions

The amount of aromatic components contained in plants is naturally limited, so attention needs to be paid for the speed and duration of the steam flow, as too much of it may cause the change in aromatic components or dilute the concentration of flower water.

Also, if the cooling pipe is not cool enough, the steam will be discharged without liquefying, The best temperature for the water flowing into the cooling pipe is 4 to 10℃.

In cases where steam distillation method is not suitable

Steam distillation is used for the extraction of many plants because it is relatively inexpensive and can be used in large quantities. However, it is not suitable for citrus plants such as lemon and bergamot. This is because when the plants are exposed to heat for long periods of time, the heat-sensitive main aroma components are changed and decomposed. (Steam distillation is sometimes used to thermally decompose phototoxic components.)

Steam distillation is also not suitable for extracting water-soluble fragrance components in oil (essential oil), as they will dissolve into water when extracted by steam distillation.

Simple distillation can be done at home. Find out the fragrance components you wish to extract are easily decomposed by heat or water soluble, and decide whether steam distillation is suitable for your extraction.

Technology in recent years

Distillation has its origins in the 8th century alchemy. A distillation device called “lambiki” was used for distillation of medicine oils and liquors in the 13th century in Japan. Lambiki as the origin of steam distillation, distillation technology has been advanced rapidly and distillation devices with various features have been developed in recent years.

The SCC (Spinning Cone Column) and Microwave Extractor are new distillation devices, and while I will not go into the technical details, one thing they all have in common is that they can perform “Decompression distillation.”

As the name suggests, decompression distillation is a method of distilling by lowering the pressure inside the still.

For example, have you ever heard that when you climb a mountain, the air pressure drops and the water boils at less than 100℃? In the same way, by lowering the pressure inside the still, the boiling point of water is lowered so that aroma components that easily change or decompose due to heat can be gathered through the steam distillation.

Depending on the equipment, some manufacturers lower the boiling point to about 40-50℃ for distillation. It seems to be able to extract a quite fresh aroma, but on the other hand, it is not suitable for extracting heavy aromas, so it is necessary to adjust the degree of pressure according to the aroma components you want to obtain.

Many types of “Steam distillation” have been developed by modern technology, and that gives us many choices of extraction we can choose from. It may be interesting to smell your fragrance with your imagination and wonder how the fragrances were extracted.

Lastly,

This issue of FRAGRANCE LAB.BLOG brought you “Extraction of Natural Fragrance Vol. 1: Steam Distillation.” Here are some products that use 100% natural fragrances extracted by steam distillation below. How about trying them out at our stores?

We hope to see you again in the next issue of FRAGRANCE LAB.BLOG.